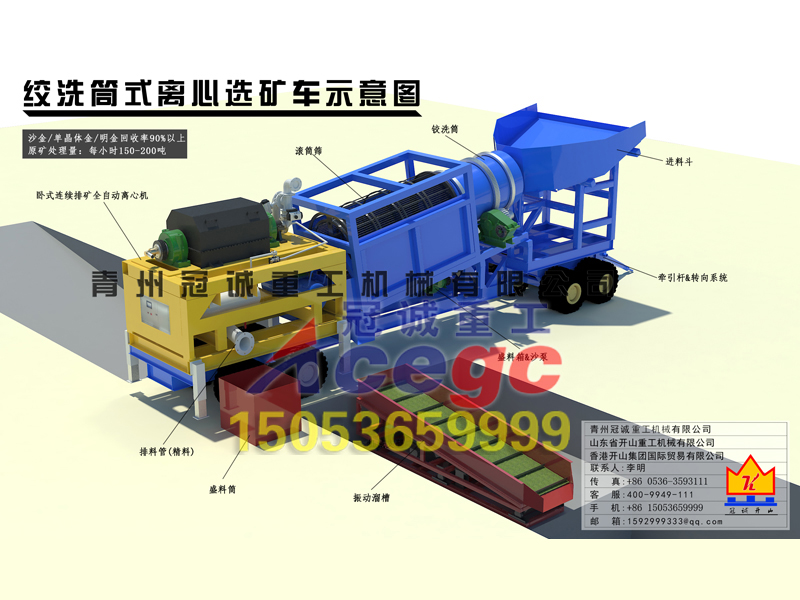

砂金設備移動式篩分離心選礦一體設備使用說明

操作說明

Operating Manual

一、操作流程

機器首次使用時要首先補充機油發電機組、柴油機、減速機內潤滑油,正常生產前先進行半小時空轉運行,檢查是否有異響等其它問題,有問題及時停機排除故障后方可進行下一步操作。

【工作流程】

開機:

1、開機順序:離心機氣泵-中轉離心泵-離心機-滾筒篩-水泵-離心泵

2、開始上料

關機:

1、首先停止上料;

2、等滾筒篩與溜槽內物料全部排出后關閉水泵;

3、關閉滾筒篩;

4、等離心機排料完成后關閉離心機;

5、關閉總電源;

Operating process

Machine used for the first time to the first supplement oil generating set, diesel engine, reducer, lubricating oil, the normal production run for half an hour before idling, check whether there is other problem such as sound, there is a problem in a timely manner offline troubleshooting rear can do next step.

Turn on:

1) . Starting steps:

Centrifuge concentrator air pump - transfer centrifugal pump - centrifuge concentrator - trommel screen -centrifugal pump

2). Start feeding

Turn off:

1). Stop the material feeding firstly;

2). Close the water pump when the material in trommel screen and sluice are discharged;

3). Close the trommel screen;

4). Close the centrifuge concentrator when discharge over of centrifuge concentrator;

5). Turn off the total power supply.

二、其它注意事項

當本機器需要移動時要把固定溜槽拆下后方可使用牽引車輛移動;使用過程中隨時注意其它問題,發現問題及時維修,若無法解決可聯系廠家。

每8小時應給軸承加油一次,柴油機保養維護請參考柴油機使用說明。

實際操作請以廠家技術員指導為準!

Others need attention

When there is a need of moving thisMinerals processing equipment,it is necessary to disassemble the fixed sluice before it’s driven to destination;During the working period please pay attention to other problems,if any problems maintain the first time, if can not solve please contact factory for technical advice.

The bearing should be refueling once every 8 hours, and the diesel engine maintenance should refer to the advice of factory engineer.

Please refer to the factory technician for the actual operation!

上一篇內容:砂金設備移動式淘金設備清單

上一篇內容:移動淘金車參數設計方案