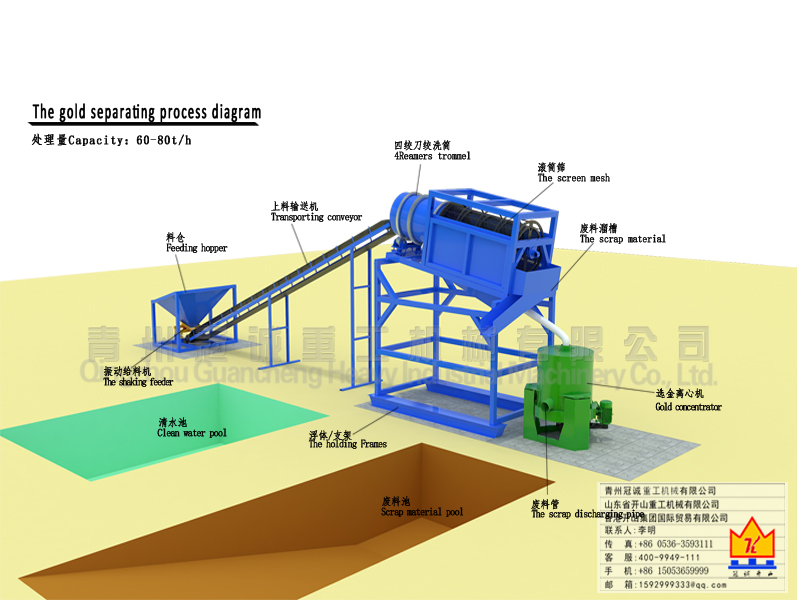

每小時60-80噸處理量巖金尾礦淘金設備

【設備簡介】

本套砂金設備為我公司根據用戶需求獨立設計制作的滾筒篩式巖金礦尾礦選金設備,處理量為每小時60-80噸,回收率60%-90%,是當今主流的砂金設備,該套砂金機械,選金礦設備,沙金選礦設備,沙金設備,選沙金機械,沙金機械具有處理量大、回收率高,設備故障率低,保養維護簡單方便等特點,主要優勢如下:

1、料倉料斗下部安裝有一臺振動給料機,防止堵料,并且可以保證給料均勻。

2、滾筒篩前端帶有鉸泥筒,內含四條鉸刀,可以有效的清洗污泥。

3、滾筒篩供水系統采用中央供水+兩側供水系統。中央供水系統負責沖洗滾筒篩內物料;兩側供水系統負責沖洗外部細篩網,防止篩網網孔堵料。

4、離心機采用一臺停機自動排礦式離心機,有效的提高了工作效率,節約了人工成本。

Brief Introduction

This set of machine designed by our company according to customer’s requirement,the capactiy is 1-3ton/hour,it works in good performance and in high recovery low failure easy maintence and the main advantage:

1).The shaking feeder under feed hopper to prevent the clogging of material,and make the material well-distributed.

2).The trommel screen with 4reamers a good result in claying ore

3).Guancheng Trommel screen using central and two flanks water supplying system,the central water supply to swill the inner material of screener,the two flanks water supplying system to clean the outer screen mesh to prevent to material clogging.

4).Gold centrifugal concentrator using horizontal auto discharge type which works efficently and reducing labour cost.

【流程簡介】

原料通過工程車輛送入料倉中,通過料倉下部的振動給料機均勻的送入上料輸送機,然后進入四絞刀絞洗筒內進行絞洗脫泥,然后進入滾筒篩內進行篩選分級為:細料與粗料兩個級別,其中粗料即廢料直接通過廢料溜槽排入廢料池中;

細料進入砂金機械,選金礦設備,沙金選礦設備,沙金設備,選沙金機械,沙金機械1400#臥式全自動連續排礦離心機內進行精選,選出的精料通過精料管不間斷排出,廢料通過廢料管排入廢料池中。

Technical process

The mineral mixture going into feed hopper then well distributed by shaking feeder to be transported with conveyor,then get into 4 reamers trommel to cut the clay and water rushed then going into screen mesh material to be classifier into 2 size 0-6mm and over 6mm,the 0-6mm material going into horizontal auto discharge gold concentrator to get gold concentrate,the size over 6mm material are getting rid into scrap material pool.

青州冠誠重工機械有限公司是砂金設備,選砂金機械,砂金機械,砂金提取機械,砂金開采設備,砂金開采生產廠家選金礦機械,選金礦設備,砂金干選設備,沙金設備,選沙金機械,砂金提取機械,砂金開采,砂金設備廠家,砂金設備價格,沙金提取設備,具體選沙金、選砂金產品有選金離心機,選金船,移動小車,振動篩淘金組合,巖金破碎機,溜槽等,歡迎咨詢

公司地址:山東省青州市黃樓街道辦事處西建德村

聯系電話:15053659999 聯系人:李明經理

上一篇內容:160噸/小時滾筒篩砂石分離設備

上一篇內容:200tph振動篩解決方案